Values

A casting manufacturing company values excellence in quality, embracing innovation and continuous improvement to produce high-quality products that meet or exceed industry standards. Operating with integrity, the company upholds ethical conduct and transparency in all business dealings. Customer satisfaction is paramount, and the company strives to understand customer needs, provide personalized solutions, and foster long-term relationships. Collaboration is encouraged, promoting teamwork and open communication both within the company and with external stakeholders. Safety is a top priority, ensuring the well-being of employees and the surrounding community. Environmental responsibility is embraced, with a commitment to sustainable practices and minimizing the environmental impact of manufacturing processes. Employee development is valued, providing training opportunities and a supportive work environment. Social responsibility is embraced through philanthropy and community engagement. The company is adaptable, embracing change and staying ahead of market demands and technological advancements.

Value Engineering

AMCON Team focuses on integrated metallurgy and value engineering approach including:

Market expertise

Our Experienced & Competent Marketing Team helps customers to meet their compliance considering our past experience in high-specification markets like industries of oil & gas, food & pharma, metal Industries & Auto sector.

Conversion assistance

High quality parts, low tooling costs, and the ability to convert fabrications, assemblies, or weldments into one-piece castings are just a few of the benefits you can achieve with the investment castings process.

Alloy selection

AMCON pours 155 plus ferrous and non-ferrous alloys grades, including customer’s specific grades. Our metallurgists works directly with customers to select alloys that meet the most demanding product & their mechanical properties.

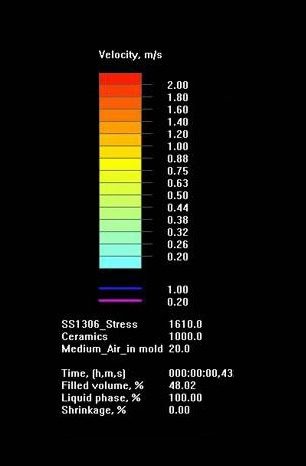

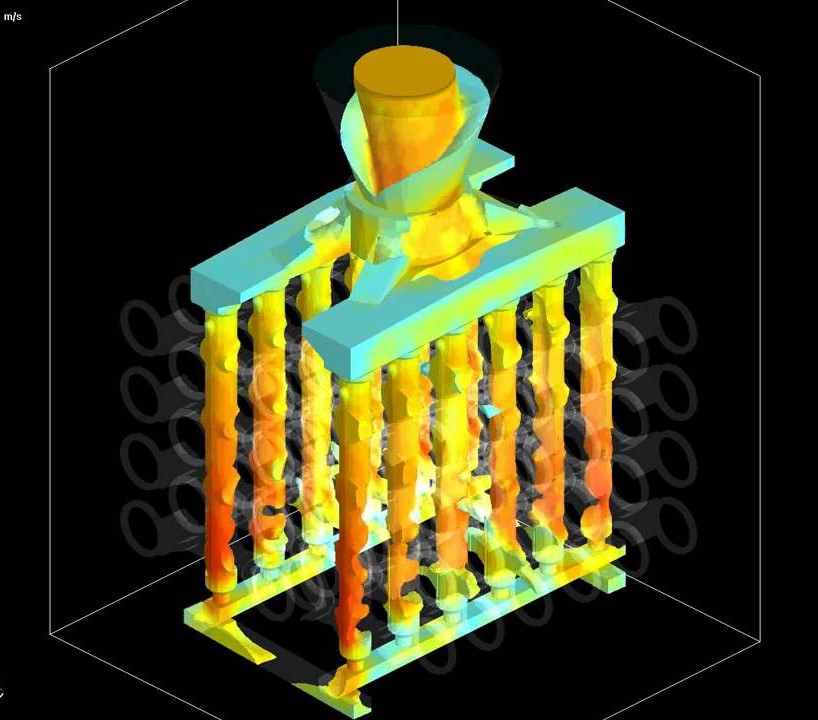

Casting process selection

Our engineers use the latest computer modeling tools to help customers determine sound castings fits their specific product needs.

Precision Machining

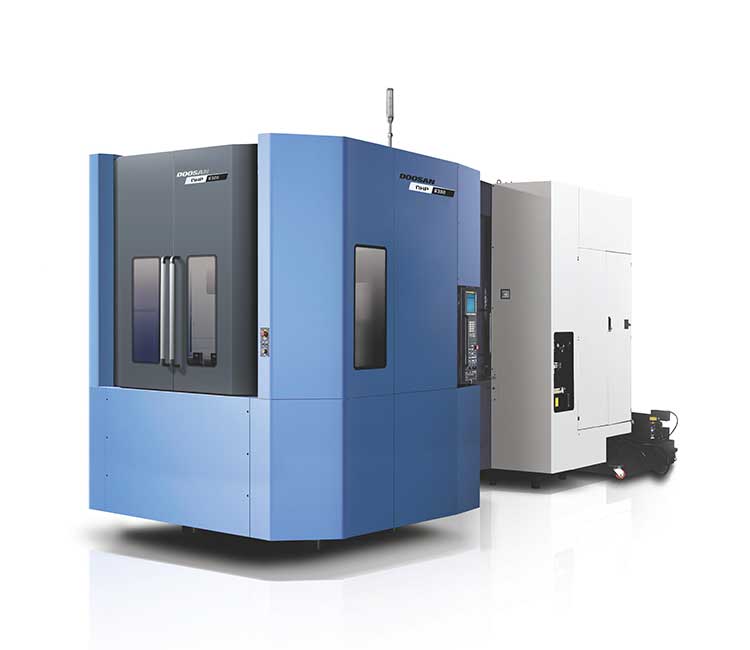

DOOSAN-HMC NHP-6300

DOOSAN-VMC DNM-6700

HAAS-VMC VF-2

MAZAK-TMC QT-C200M

HAAS-TC ST-20

HAAS-TC ST-30

DOOSAN-TC PUMA-2600